Felgenprofessor

Manual sandblasting cabin with integrated filter system

Manual sandblasting cabin with integrated filter system

Couldn't load pickup availability

Description

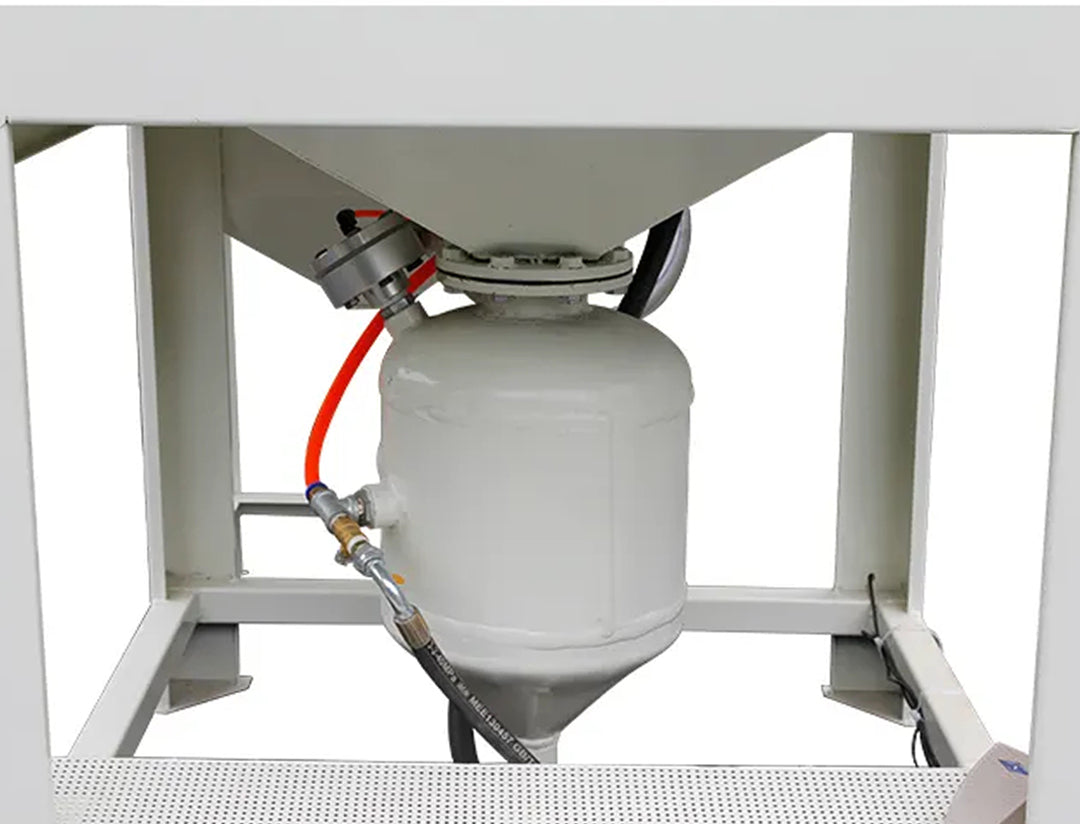

The manual sandblasting cabin including filter system from rim professor is the number 1 among the pressure blasting cabins for professional sandblasting - ideal for permanent use for materials such as e.g. B. aluminum, steel, cast iron, stainless steel. Equipped with a boron carbide blasting nozzle and a rotatable turntable (360°), sandblasting is a breeze. The abrasion caused by the blasting medium is increased by the pressure tank and thus even the most stubborn unevenness is smoothed out.

To ensure that the reusable particles are not lost, our blasting cabin has an extractor for pre-filtering and an integrated dust extraction system for final air treatment in breathable air quality. The fine dust particles are thus separated from the other blasting particles and filtered out in the dust extraction.

The manual pressure blasting cabin was developed for efficient use and meets the highest quality standards in terms of durability and workmanship.

Experience a new dimension of sandblasting!

The manual sandblasting cabin including filter system - from the rim professor for professionals!

service

We offer our customers energy-efficient products and system solutions as well as delivery, service, maintenance and spare parts supply. Visit the machine on site in our exhibition!

Our product specialists can create any configuration for your projects with any of our systems.

Contact us today for an offer!

financing

Do you need help financing the product? For all our machines and systems, we offer you the option of financing them by hire purchase or leasing at interesting conditions with or without a down payment. Please contact us!

Shipment

If the product is in stock, you have the choice of picking it up yourself or having it delivered for a fee.

If the product is not in stock, it will be made to order at the factory and shipped directly to you. Alternatively, the product can be delivered to our warehouse for collection. Fast production time of 4-8 weeks.

The machines are usually dispatched by a forwarding company. The costs for this are not included in the purchase price! We choose the best shipping service provider at the time of purchase and tell you the costs. You are also welcome to ask us about the current shipping costs before you buy, which we will inform you of in a binding manner.

Technical specifications

Type of nozzle: Borcabid jet nozzle

Mains voltage: 380 V / 50-60 Hz

Power consumption (full load): 0.75 KW

Compressed air supply: dry compressed air with up to 5-8 bar

Cabin size: 1000 x 1000 x 800 mm

Overall Size: 1650*1200*2100mm

Max. load turntable: 100 kg

Weight: 500kg

Accesories

• Sandblasting gun with boron carbide nozzle

• Air gun

• Compressed air hose

• Sandblasting Gloves

Customer-side errands for operational readiness

1. Run the 380V electric wire to the control panel and ground the machine.

2. Installation and, if necessary, connection of compressed air lines.

3. Continuous dry air supply of 8 bar 2 m³/h for the blasting system.

4. Provision of the necessary blasting granules for the sandblasting process.