Felgenprofessor

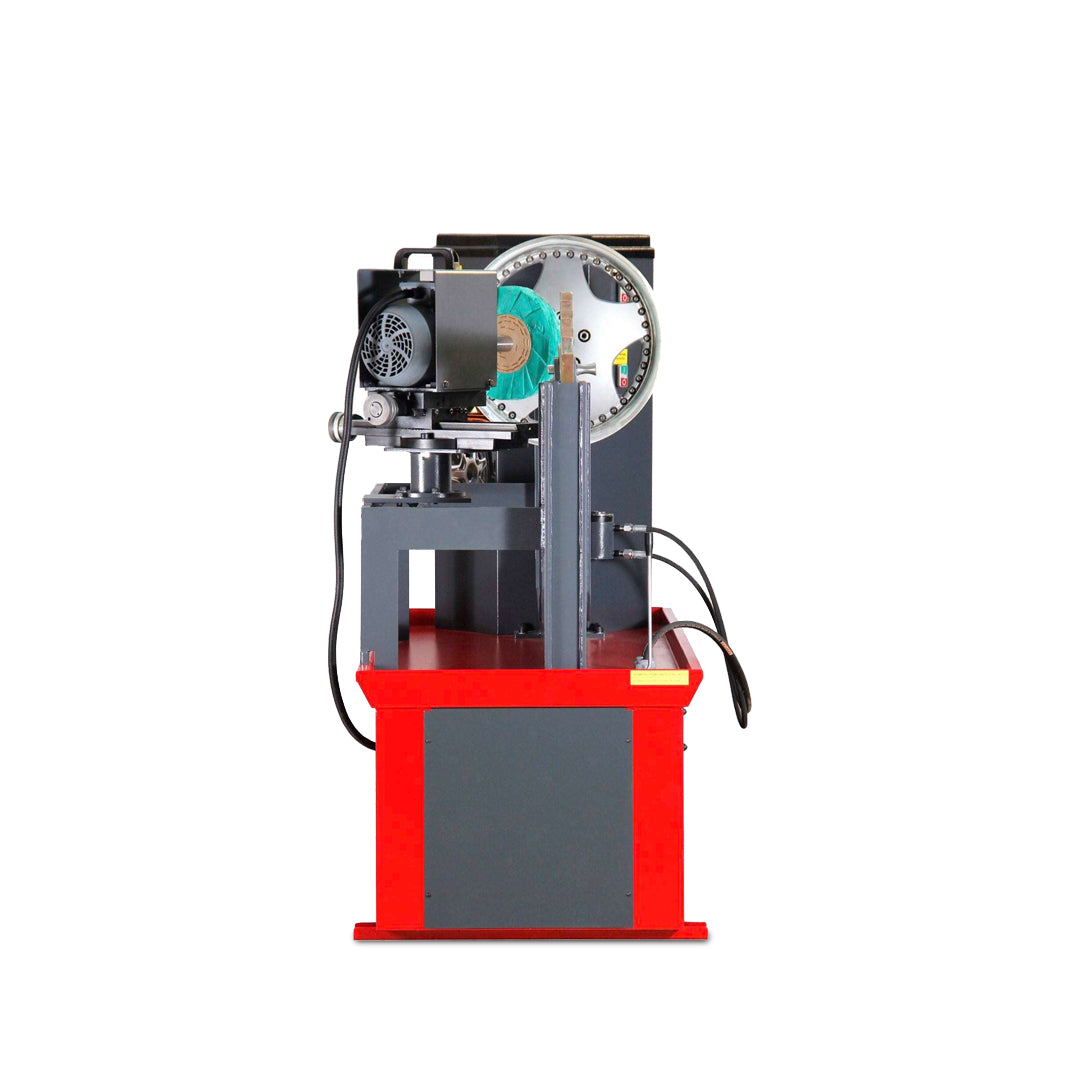

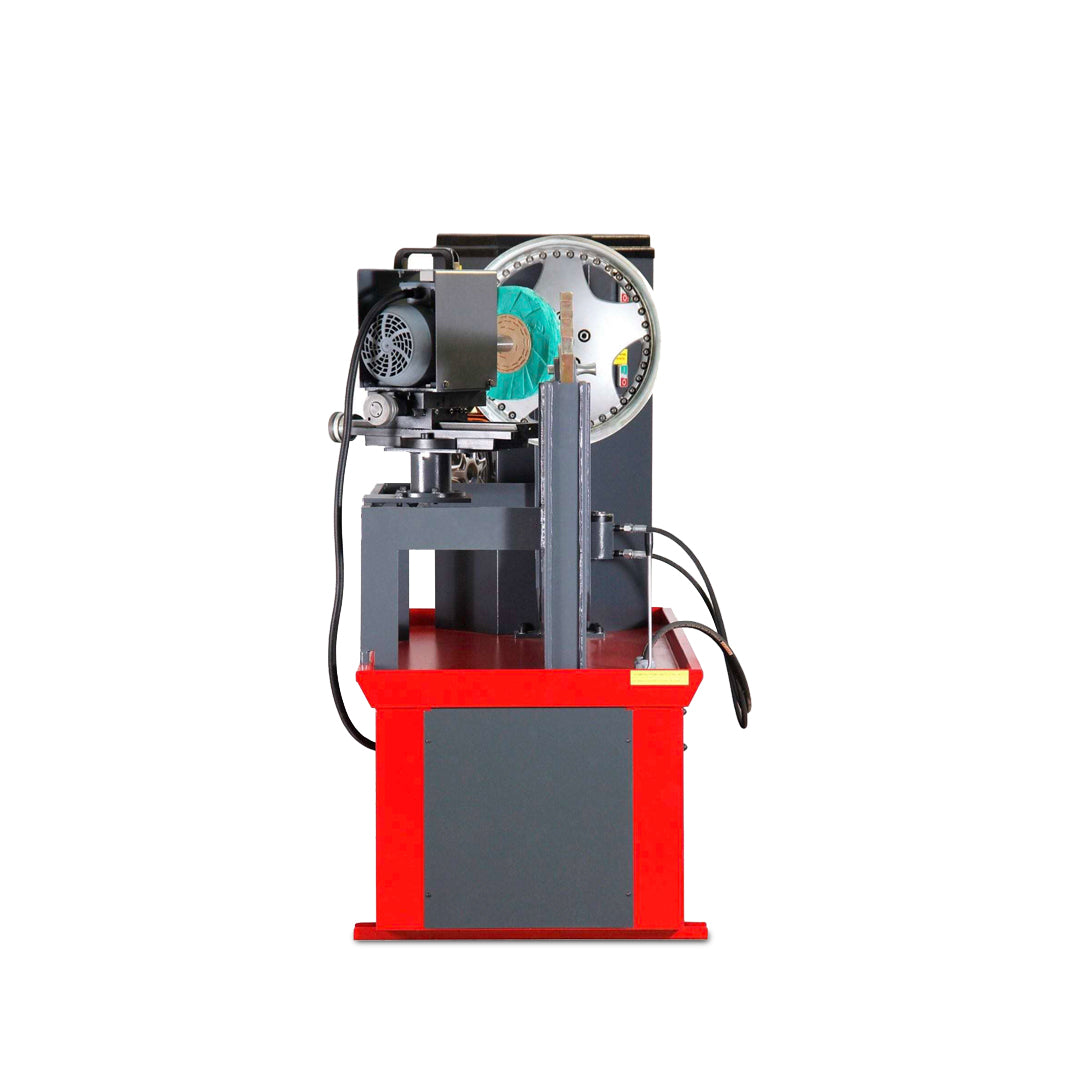

Rim straightening machine with polishing system | Rim Repair | Rim repairs up to 30 inches

Rim straightening machine with polishing system | Rim Repair | Rim repairs up to 30 inches

Couldn't load pickup availability

Description

With the rim professor rim straightening machine FPR-30 incl. polishing system, concentricity damage in the form of radial and lateral run-outs are gently corrected with the help of the 5-ton hydraulic cylinder in combination with external heat supply. The rim straightening machine is equipped with a piston driven by a hydraulic system. With this piston you press on the damaged part of the rim and give it back its original shape. Additional heating, e.g. with a burner, allows the aluminum to be processed more easily and gently. Thanks to our modern rim straightening machine, you can straighten rims up to a diameter of 30 inches .

Advantages

- perfect repair effect

- simple operation

- workable wheel diameter: up to 660 mm (10 - 30 inch wheel size)

- hydraulically controlled piston system

- stepless speed change

- offset distance detection

functions

- Repair of various light alloy rims with damage such as warping or deformation from radial and lateral impacts

- distance detection

- positioning mark

- straighten edge

- rotary cutting etc.

Furnishing

- Model identification: FPR-30

- polishing system

- Lathe and accessories

service

Only a short briefing is required to use our straightening machine. However, our team is also at your side for training courses and also helps future rim professors!

On request, we will be happy to send you an application video.

We offer our customers a selection of energy-efficient products and system solutions as well as delivery, service, maintenance and spare parts supply.

financing

Do you need help financing the product?

For all our machines and systems, we offer the option of financing them by hire purchase or leasing at interesting conditions with or without a down payment. Please contact us!

Shipment

If the product is in stock, you have the choice of picking it up yourself or having it delivered for a fee.

If the product is not in stock, it will be made to order at the factory and shipped directly to you. Alternatively, the product can be delivered to our warehouse for collection. Fast production time of 1-2 weeks.

The machines are usually dispatched by a forwarding company. The costs for this are not included in the purchase price! We choose the best shipping service provider at the time of purchase and tell you the costs. You are also welcome to ask us about the current shipping costs before you buy, which we will inform you of in a binding manner.

Technical specifications

• Wheel size range: 10 – 30 inches

• Hydraulic motor: 0.75 kW, 1400 rpm

• Mechanical motor: 0.75 kW, 1400 rpm

• Hydraulic pump capacity: 5 tons

• Mains voltage: 220 V / single phase – 380 V / 3-phase – 50/60 Hz

• Dimensions (W/D/H): 1660 x 800 x 1540 mm

• Weight: 450 kg

• Loudness: 40-45dB