Felgenprofessor

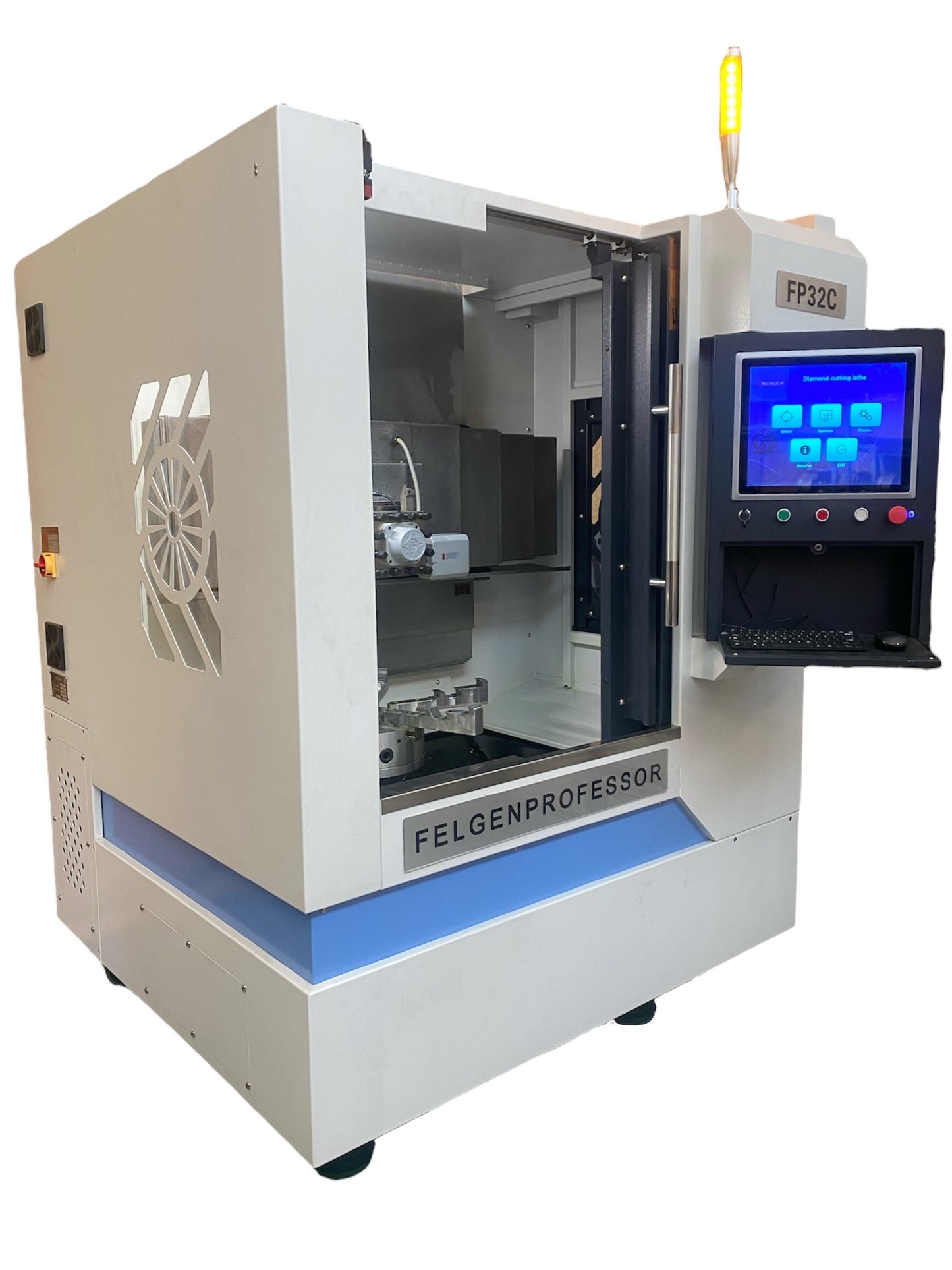

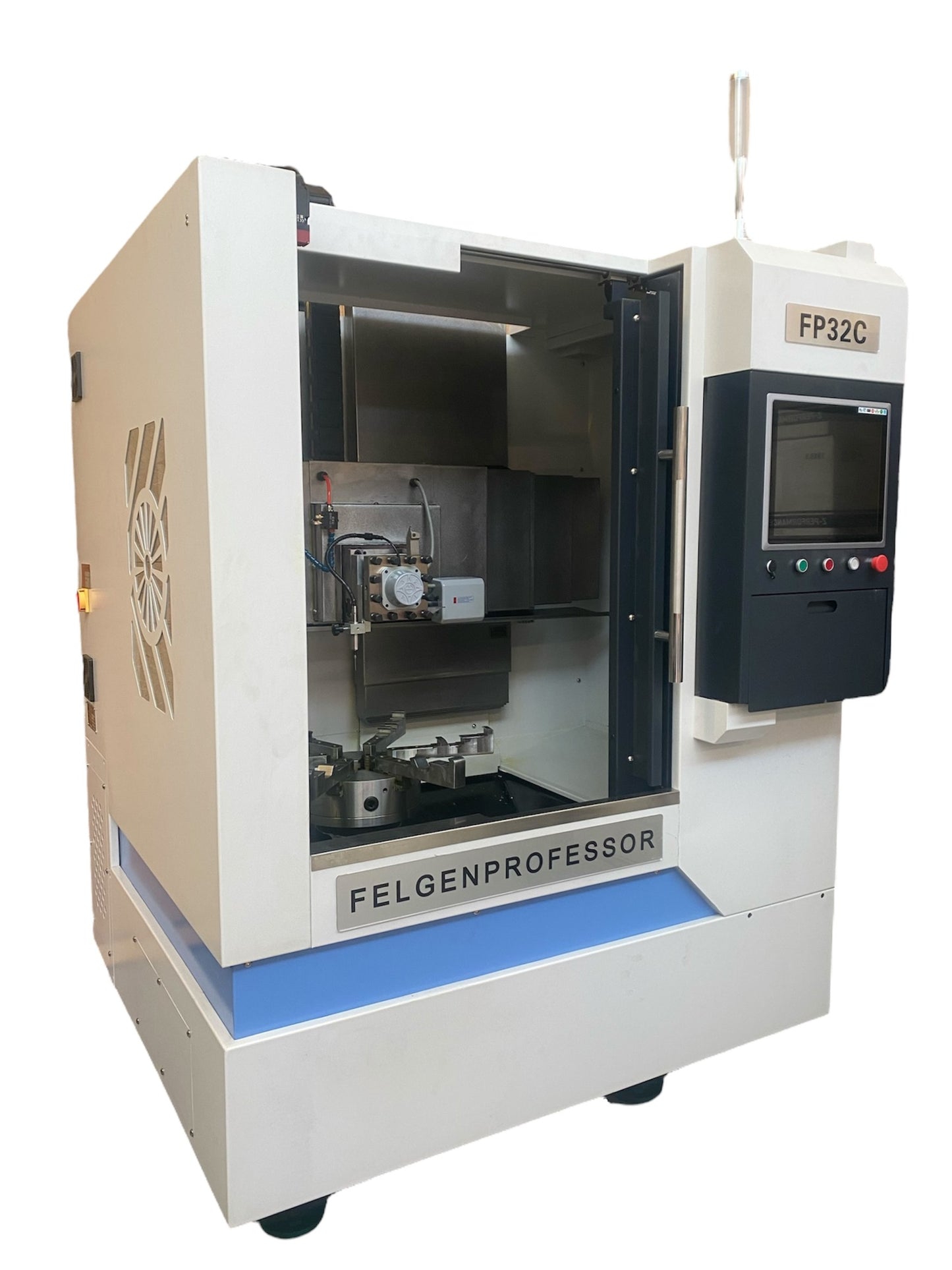

CNC Wheel Polishing Lathe FP32C

CNC Wheel Polishing Lathe FP32C

Couldn't load pickup availability

Description

Rim Professor's CNC bright turning machine FP32C - the fully automatic repair machine for bright turning on aluminum rims.

The automatic rim repair machine enables effective repair of burnished surfaces according to the highest quality standards and the best results. The processing of the different types of rims can be carried out in a very short time.

What are the significant advantages of our CNC solutions for burnishing wheel rims?

- The inclusion of the inner rim flange with the precision six-jaw chuck prevents vibrations during burnishing and thus leads to an optimal surface finish.

- Contour database: Each rim type only has to be recorded once.

- Rotation pattern and degree of gloss infinitely adjustable through spindle speed and feed.

- Optimum rotation even at low speeds (300 rpm) possible (maximum spindle speed 2,000 rpm).

service

Through daily use in our own repair shop and in the processing of new wheels, new ideas are constantly being created. These are immediately included in the development and implemented.

Would you like to see our CNC wheel processing machines for yourself?

We would be happy to invite you to a demonstration in our company so that you can convince yourself of the CNC complete solution!

We offer our customers energy-efficient products and system solutions as well as delivery, service, maintenance and spare parts supply.

Our product specialists can create any configuration for your projects with any of our systems.

financing

Do you need help financing the product? For all our machines and systems, we offer you the option of financing them by hire purchase or leasing at interesting conditions with or without a down payment. Please contact us!

Shipment

If the product is in stock, you have the choice of picking it up yourself or having it delivered for a fee.

If the product is not in stock, it will be made to order at the factory and shipped directly to you. Alternatively, the product can be delivered to our warehouse for collection. Fast production time of 4-8 weeks.

Technical specifications

- Machining of rims 12" to 32"

- Microprocessor control

- Manual chuck with 6-jaw chuck

- Automatic scanning system for recording the rim contour

- Automatic spindle speed control: 50-2000 rpm

- Uneven over-spin to match and interpolate

- 4-fold manual tool holder (also available as an automatic version)

- Suitable for wet or dry machining

- Machining of drop center rims

- No manual preparatory work necessary

- Support and parts service available

- Training either in our company or at your site

- Weight: 1300KG

- Dimensions LxWxH: 1460x1570x2030mm